Granite Tombstone Export from India: Trusted Manufacturers & Global Suppliers

Granite Tombstone Export from India, When it comes to honoring the memory of a loved one, the choice of material for a tombstone is a decision that lasts for generations. Granite has long been the gold standard for memorials due to its incredible durability and natural beauty. Today, India stands as a global powerhouse in this industry, recognized as a leading exporter of premium granite tombstones and monuments.

In this blog, we will explore why Indian granite is the preferred choice for global suppliers, how these monuments are crafted, and how to find trusted manufacturers for your needs.

Why India is the Global Leader in Granite Tombstones

India is home to some of the world's largest and most diverse granite reserves. With over 250 varieties of colors and patterns, the Indian stone industry offers a level of choice that few other countries can match. But it isn't just about the variety; it's about the quality.

- Unmatched Durability

Granite is one of the hardest substances on Earth, second only to diamond. Indian granite is particularly known for its high density and low water absorption. This means that a tombstone carved from Indian stone can withstand harsh winters, heavy rains, and scorching summers without cracking or losing its luster.

- A Spectrum of Colors

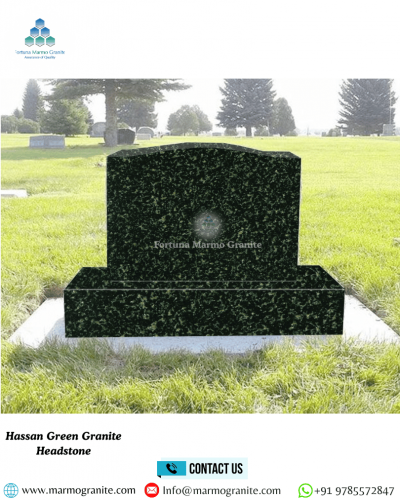

While "Absolute Black" is the most popular choice for its classic and dignified look, Indian manufacturers export a wide range of unique colors:

- Black Galaxy: Featuring natural golden specks that look like stars.

- Vizag Blue: A serene, bluish-grey tone popular in European markets.

- Imperial Red: A deep, bold red symbolizing strength and legacy.

- Kuppam Green: A tranquil green that blends beautifully with natural cemetery landscapes.

- Cost-Effectiveness

Because India has a massive infrastructure for quarrying and processing, it can offer premium-quality stones at much more competitive prices than suppliers in Europe or the Americas. This allows global buyers to get "luxury" quality at wholesale rates.

The Journey: From Indian Quarries to Global Memorials

Step 1: Ethical Quarrying

The process begins in the quarries of South India (like Karnataka and Andhra Pradesh) and North India (Rajasthan). Massive blocks are extracted using diamond wire saws to ensure the stone doesn't develop internal cracks.

Step 2: Precision Cutting and Shaping

Once the blocks reach the factory, they are sliced into slabs using advanced Italian-made machinery or CNC (Computer Numerical Control) machines. This ensures that the thickness is consistent—a crucial factor for international quality standards.

Step 3: Polishing to a Mirror Finish

This is where the stone truly comes to life. Multiple rounds of polishing using varying "grit" levels give the granite a glossy, mirror-like finish. This isn't just for looks; a high polish protects the stone from environmental erosion.

Step 4: Custom Carving and Engraving

Modern Indian suppliers use laser engraving and sandblasting to create intricate designs. Whether it's a religious symbol, a detailed portrait, or a custom message in a specific language, the precision is world-class.