Why Add Fiber to Granite Slab Backgrounds? Key Benefits Explained

Why Add Fiber to Granite Slab Backgrounds ,with its timeless beauty and exceptional durability, has long been a top choice for countertops, flooring, and wall cladding. Its natural elegance adds a touch of luxury to any space, making it a favorite among homeowners and designers alike. To enhance granite's inherent strength, resilience, and versatility, manufacturers have begun integrating fiberglass mesh into the back of granite slabs.

This simple addition proves to be a game-changer. It not only reinforces the stone but also safeguards your investment, ensures safer installation, and extends the lifespan of the slab. In this blog, we explore the key benefits of adding fiberglass backing to granite and explain why this small detail makes a major difference.

Moreover, Fiber backing addresses many challenges traditionally associated with natural stone, such as cracking, chipping, or breaking during transportation and installation. Granite is heavy and brittle, and even minor mishandling or structural movement can cause damage. In addition, The fiberglass layer stabilizes the slab, providing essential tensile strength and helping it resist flexural stress and physical impact.

1. Enhanced Strength and Durability: The First Line of Defense

Granite, though known for its hardness and durability, is not completely immune to damage. As a natural stone, it has inherent fissures, hairline cracks, and structural weaknesses. These imperfections can result from quarrying or fabrication. Often invisible to the naked eye, they make the slab vulnerable to breakage during handling and transportation.

This is where the fiberglass mesh acts as a powerful reinforcement. Think of it as a skeletal system for the stone. The mesh is securely bonded to the back of the slab, creating a robust, unified structure. This prevents the slab from cracking or shattering under stress, making it far more resistant to impact from drops, bumps, or pressure. This added strength is particularly crucial for large, thin, or irregularly shaped slabs, which are more susceptible to breakage.

2. Prevention of Cracking and Breakage During Fabrication and Installation

Moreover ,The journey of a granite slab from the quarry to your home is a long one, involving cutting, polishing, and installation. This process is where most of the damage occurs. A slab without a fiberglass backing is a fragile commodity during this phase. A single misstep, a slight wobble, or an uneven surface can cause a crack to propagate and run through the entire slab. This can lead to significant material loss, project delays, and increased costs.

With a fiberglass backing, the risk is significantly minimized. The mesh holds the slab together, containing any cracks that might form. This means that even if a fissure does develop, the slab remains in one piece, allowing the fabricator to work on it without the risk of it falling apart. This not only saves material but also ensures a smoother, more efficient installation process. It acts as an insurance policy, protecting your investment from the moment it leaves the warehouse.

3. Increased Safety for Fabricators and Installers

Safety is the top priority for everyone handling granite. A sudden breakage of a large slab can cause serious injuries. Sharp edges of a shattered stone can cut deeply, and the slab's heavy weight can crush.

Adding a fiberglass backing greatly reduces these risks. If a crack forms, the mesh keeps the pieces together, preventing the slab from collapsing. This creates a safer workspace for fabricators cutting the stone and installers lifting it. A simple addition, yet it has a profound impact on safety.

4. Versatility and Design Freedom

The added strength provided by the fiberglass backing opens up a world of possibilities for designers and architects. Previously, certain intricate designs or large unsupported spans were risky with unsupported granite slabs. Now, with the reinforcement, you can create more dramatic and innovative designs without compromising on structural integrity.

In addition, This means you can have thinner, lighter slabs for applications like wall cladding, where weight is a concern. You can create unique shapes, intricate patterns, and cantilevered countertops with greater confidence. The backing allows the stone to be more flexible, enabling it to be used in applications that were once deemed too risky.

5. Simplified Handling and Transportation

Transporting a heavy, delicate granite slab is a logistical challenge. Without proper reinforcement, a slight bump in the road or a sudden turn can lead to catastrophic damage. The fiberglass backing makes the slab more manageable and easier to handle. It reduces the risk of chipping and breakage during loading, unloading, and transportation. This results in less waste and fewer logistical headaches for suppliers and installers.

6. A More Uniform and Stable Surface

The fiberglass mesh on the back of the slab provides an even surface, which is essential for proper adhesion. This ensures that the slab is securely bonded to the substrate, preventing any warping or movement over time. A uniform surface also makes the installation process more straightforward and less time-consuming, resulting in a flawless finish.

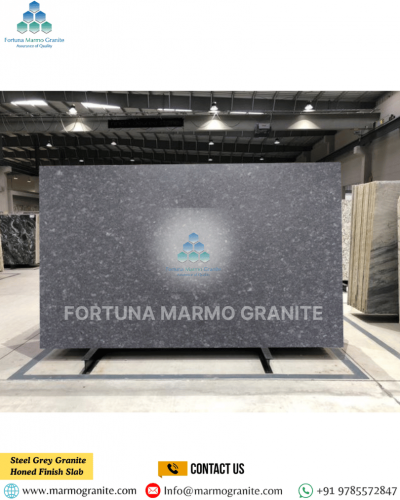

Why Choose Fortuna Marmo Granite?

When it comes to high-performance granite slabs enhanced with fiberglass backing, Fortuna Marmo Granite stands out as a trusted and innovative leader in the industry. As a leading granite manufacturer and exporter from India, we combine traditional craftsmanship with advanced techniques to produce slabs that meet global standards of strength, safety, and aesthetics.

What sets us apart is our commitment to quality and innovation. We engineer our granite slabs with fiber backing for superior durability, reducing breakage during handling, transportation, and installation. Whether you need slabs for countertops, wall cladding, or large-format flooring, our reinforced products provide the extra stability your project demands.

Conclusion

In conclusion In today's competitive and quality-driven construction and design industry, clients demand natural stone products that are stronger, safer, and more durable. Adding fiber reinforcement to granite slab backgrounds has emerged as one of the most effective innovations to meet this need. Consequently, This approach goes beyond being a trend—it provides a practical solution that enhances the structural integrity of granite slabs while preserving their natural beauty and surface finish. Fiber-backed granite resists cracking more effectively, making it an excellent choice for both residential and commercial projects, especially for long spans or large-format installations.

Moreover, At Fortuna Marmo Granite, we are proud to stay ahead of the curve by offering premium granite slabs with fiber backing options that combine the timeless elegance of natural stone with cutting-edge reinforcement technology. In addition, As a trusted Indian granite manufacturer and global exporter, we are committed to delivering products that not only meet international quality standards but also exceed customer expectations in durability, performance, and aesthetics. By choosing fiber-reinforced granite from Fortuna Marmo Granite, you invest in a solution that blends innovation with natural beauty—ensuring strength, reliability, and sophistication for every space.