Types of Granite Finishes

Granite is one of the most popular materials for kitchen and bathroom countertops, and for good reason. Its stunning patterns and wide range of finishes make granite countertops the focal point of any space. In fact, designers often select the unique colors or patterns of granite first in high-end kitchens and bathrooms, then plan the rest of the décor around it.

This natural stone is not only beautiful but also highly durable. Granite resists heat, scratches, and stains, making it a practical choice for busy homes. Moreover, granite comes in over 600 colors and patterns, offering nearly endless design possibilities. Its versatility allows it to be used for outdoor décor, fireplace surrounds, vanity tops, and, of course, kitchen countertops, combining elegance with long-lasting functionality.

Granite is one of the most versatile natural stones, making it a top choice for both residential and commercial projects. When carefully polished to a high-gloss, reflective surface, it is known as polished granite. Its reflective quality adds a touch of luxury and sophistication to any space. Interior designers frequently select granite for construction and remodeling projects, and for good reason. It is available in a wide range of colors and patterns, combines strength with elegance, and remains cost-effective. Therefore, understanding the different granite surface finishes is essential for making the most of this remarkable natural stone.

Let's examine types of stone surfaces in detail

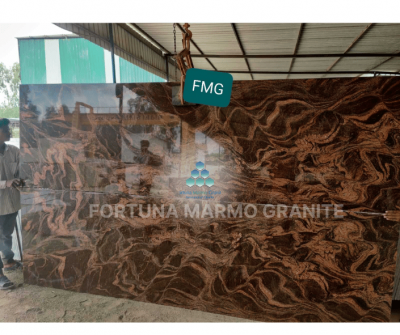

Polished Finish

For granite countertops, polished is the most typical finish. The polished surface of the granite slab gives it a glossy, nearly mirror-like appearance. The qualities of the stone are accentuated with a polished finish. The textures and colors will be more vivid.

This is the finish that is used the most frequently on granite surfaces. The main goal of using this treatment is to bring out the natural beauty of the stone and provide elegance to any room. A granite surface with a polished finish has a reflective sheen that dazzles observers. This polish is renowned for bringing out the granite's natural beauty and colour.

Nearly all countertop surfaces are given a polished finish, which is similar to an intrinsic aspect of stone processing and makes the surface slicker. In a similar vein, floorings frequently use this finish. The polishing process in granite factory involves grinding and buffing to give the stone's surface a glossy, slick appearance. The stone slab travels through several polishing rollers with abrasive pads attached. By applying pressure to the stone and grinding and buffing the surface, these pads polish the stone. In order to get the desired gloss, the pad intensity is measured in grits and starts at 50 grit, and reaching up to 3000 grit to attain the desired gloss.

Honed Finish

A super smooth surface without any gloss or reflection is produced by a honed finish, often known as a matte or buffed finish. This finish is produced by stopping the normal polishing procedure before the stone is polished to provide a flat finish, often known as a satin finish. Honed finishes are most frequently used on floors to prevent people from tripping over polished stones' slick surface. Although granite counters can also have this polish, it renders the material more prone to stains.

This surface treatment is quite popular for counters because it produces a finish that is smoother and more workable. A honed finish also has the advantage of hiding defects better than other finishes because it is less reflecting.

A honed surface is suitable for flooring as well because it is less slippery and shows signs of use or traffic patterns. A polished surface is more effective in retaining moisture than an honed finish. You might need to reseal granite more frequently than polished granite since honed granite is less slippery and stain-resistant. You won't have to polish the stone, though.

3. Leather finish/CARESSED

A very recent finishing technique is the leathered finish, often known as the brushed finish. It is made by applying texture with subtle dimples to a sharpened surface using diamond-tipped brushes. Finishes with leather tend to look more upscale. Unlike countertops with a honed surface, leathered countertops frequently retain the color of the natural stone.

This is relatively new compared to other granite surface finishes and is quickly gaining appeal in the décor sector. It has a rough appearance and a slight shine that is less polished.

When compared to honed granite, leathered granite Types of Granite Finishes will be more stain-resistant since the texture will vary from piece to piece and certain natural stones will have a more pronounced leather finish than others. This surface treatment conceals fingerprints, water stains, and smudges.

Applications: Bar tops, bathrooms, fireplace covers, and specially made tables

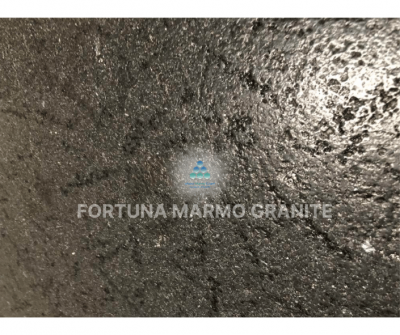

Flamed finish

A flamed finish is achieved by applying extreme heat to the granite surface, a technique that only works on certain types of granite. As a result, this finish is relatively uncommon and is more frequently used in outdoor kitchens than indoors. During the process, granite is exposed to very high temperatures, which causes the stone's grains to burst and alters its color. Consequently, the surface becomes rougher, with a slightly aged and rustic appearance. Flamed-finished countertops often display subdued, natural colors, giving them a unique charm.

Additionally, the finishing process creates a slightly uneven texture and lightens the stone subtly, enhancing its weathered and rustic look while maintaining durability and slip resistance.

This finish is made by exposing the stone surface to a high-intensity flame, which causes the surface to spurt and become gritty, as its name suggests. For outdoor applications where a non-slip surface is required, it is the perfect finish. Applications: Paving, outside walls, and outdoor kitchen

5. Lapotra Finish

The term "Lapotra" originates from Italy. To achieve a Lapotra finish, craftsmen first grind the granite surface with an abrasive to remove the existing polish. Then, they use additional stone abrasives to remove scratches and prepare the surface for the leather finish. Next, the leather texture is applied using stone brushes in progressive grits: 26, 60, 80, 120, 240, 320, and 500. Finally, three specialized abrasives—800, 1500, and 3000—are applied to achieve a balanced finish that is both muted and subtly glossy. Granite with a Lapotra finish features a grainy, slightly tarnished look that is highly stylish. Moreover, its surface is non-slippery, easy to clean, and ideal for both aesthetic and practical applications.

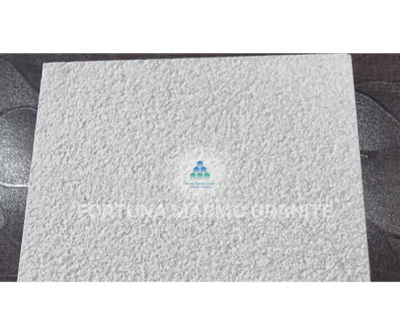

6 . Bush Hammered Finish

Bush-hammering produces this unique finish by repeatedly striking the stone with steel brushes, which break the surface and create tiny cracks. This technique creates exceptionally slip-resistant surfaces, similar to the flamed finish described above. It can also replicate the look of a rough polish from the era when stones were hand-chiseled. Finally, light steel brushing adds a subtle "time-worn" effect, giving the stone a rustic and aged appearance.

Conclusion

In conclusion, understanding the types of granite finishes is essential for selecting the right look and functionality for your project. From polished and honed surfaces that enhance elegance to flamed, brushed, and leathered finishes that offer texture and slip resistance, each finish serves a specific purpose and complements different design styles. The choice of finish not only affects the aesthetic appeal but also influences durability, maintenance, and overall performance.

Types of Granite Finishes, At Fortuna Marmo Granite, we provide a wide range of expertly processed granite finishes, ensuring consistent quality, precise workmanship, and long-lasting beauty. Our selection allows you to achieve the perfect combination of style and functionality for countertops, flooring, wall cladding, and other architectural applications.