Custom Size Granite for Commercial Projects: Precision Stone Solutions for Modern Spaces

Custom Size Granite for Commercial Projects, In the world of modern architecture and commercial design, first impressions aren't just important—they are everything. Whether it's a high-end hotel lobby, a sprawling corporate office, or a luxury retail space, the materials used speak volumes about the brand's quality and stability.

Among all the materials available, granite remains the undisputed king. But today, "off-the-shelf" slabs are no longer enough. To truly stand out, developers and designers are turning to custom-size granite solutions.

This blog explores why precision-cut granite is the secret weapon for modern commercial projects and how it transforms ordinary spaces into extraordinary landmarks.

Why Custom-Size Granite is a Game Changer

- Perfect Fit for Unique Layouts

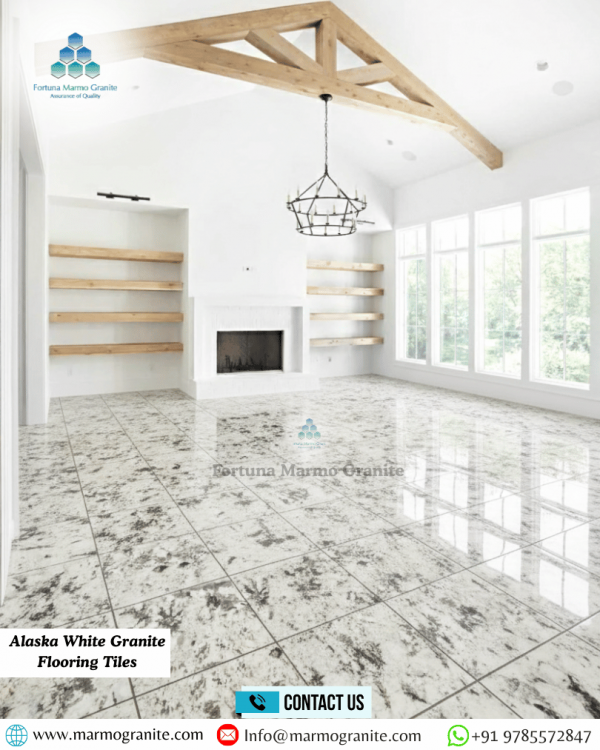

Modern commercial buildings are rarely just boxes. They feature curved walls, massive open atriums, and intricate geometric designs. Standard granite tiles often lead to "patchwork" patterns that ruin the visual continuity.

By ordering custom-cut slabs, project managers ensure that every piece fits the architectural blueprint exactly. This reduces the need for onsite cutting, which saves time and minimizes dust and noise pollution.

- Reduced Material Waste

In large-scale commercial projects, every square foot counts toward the budget. When you use standard sizes, you often end up with significant "off-cut" waste. Custom sizing allows for precision ordering. You get exactly what you need, which is not only cost-effective but also more environmentally friendly.

- Structural Integrity

Large-format custom slabs mean fewer grout lines. In high-traffic commercial areas, grout is often the first thing to wear down or get dirty. By using larger, precision-fit granite pieces, you create a more hygienic and structurally sound surface that can withstand the heavy foot traffic of a busy shopping mall or airport.

Applications: Where Precision Stone Shines

Grand Entrances and Lobbies

The lobby sets the tone for the entire building. Large-scale granite flooring with custom inlays or "book-matched" patterns (where two slabs mirror each other) creates an immediate sense of luxury. Custom sizes allow for massive, sweeping floor patterns that guide the eye toward the reception desk or elevators.

Exterior Cladding

Modern skyscrapers use granite cladding to combine beauty with durability. Since every building has a different height and wind-load requirement, the granite panels must be cut to precise thickness and dimensions. Custom granite can handle extreme weather while maintaining its color for decades.

Corporate Boardrooms

In the world of business, a solid granite conference table is a symbol of strength. Creating a 20-foot table requires a single, massive custom-cut slab or several perfectly matched pieces that appear as one.

High-End Retail and Hospitality

Luxury brands use custom stone to create a "signature look." Whether it's custom-carved granite shelving or unique checkout counters, precision stone solutions allow designers to play with textures and shapes that standard materials simply can't achieve.

The Technology Behind the Precision

You might wonder: How do they get it so perfect? The journey from a raw mountain block to a polished, custom-fit slab involves incredible technology.

- CNC Machining: Computer Numerical Control (CNC) machines use digital blueprints to cut granite with a precision of within a fraction of a millimeter.

- Waterjet Cutting: This technology uses high-pressure water mixed with abrasives to cut intricate curves and patterns that would be impossible with traditional saws.

- Digital Templating: Before a single stone is cut, technicians use laser scanners to create a 3D map of the commercial space, ensuring the stone will fit like a glove.

The Benefits of Partnering with a Custom Stone Provider

Designing for the Future: Sustainability and Granite

In 2026, "green building" is no longer an option—it's a requirement. Granite is a natural, 100% recyclable material. Unlike synthetic surfaces, it doesn't off-gas harmful chemicals (VOCs).

By choosing custom sizes, you are practicing "Sustainable Sourcing." You are utilizing the stone more efficiently, reducing the carbon footprint associated with shipping waste material, and ensuring the longevity of the building. A granite floor doesn't need to be replaced every 10 years like carpet or laminate, making it one of the most eco-friendly choices for long-term projects.

Simple Steps for Your Commercial Project

If you are a developer or an architect planning your next project, here is how to approach custom granite:

- Consult Early: Bring your stone specialist into the design phase. They can advise on which granite types (like Absolute Black, Blue Pearl, or Imperial White) are best suited for custom large-scale cuts.

- Focus on the Finish: Custom doesn't just mean size; it means texture. Choose from polished (shiny), honed (matte), or flamed (rough/slip-resistant) finishes depending on the area's use.

- Verify the Source: Ensure your provider has the machinery to handle "Jumbo Slabs" if your design requires massive, unbroken pieces.