Steel Grey Granite Manufacturer from India: A Bold Blend of Strength and Style

Steel Grey Granite Manufacturer from India In today's architectural landscape, quality, longevity, and visual harmony are essential. Steel Grey granite is a popular choice for its strength and refined beauty. Its blend of dark and light grey tones, speckled with crystalline patterns, creates a versatile appeal. The stone works well in both modern and classic designs. From kitchen countertops and bathroom vanities to commercial flooring and wall cladding, Steel Grey granite adapts seamlessly to many applications.

Manufacturers combine advanced technology with decades of craftsmanship to process each slab with precision. They offer multiple finishes, including polished, honed, flamed, leathered, and brushed. This range gives designers and architects the freedom to achieve the look they want. Exporters in India, such as Fortuna Marmo Granite, uphold strict quality standards and deliver slabs in different dimensions and thicknesses. They are known for timely shipments, consistent quality, and customized solutions for every project.

Crafting Elegance: The Manufacturing Process

- Precision Cutting: Large granite blocks are transported to the factory where they are fed into powerful gang saws or multi-blade cutters. These machines, equipped with diamond-tipped blades, slice through the stone with incredible precision, creating slabs of varying thicknesses. The manufacturer's investment in advanced machinery ensures consistent dimensions and minimal wastage.

- Expert Polishing: The raw slabs have a dull, rough surface when first cut. During polishing, the true character of Steel Grey granite emerges. Multi-head machines with progressively finer abrasive pads refine the surface until it achieves a mirror-like, high-gloss finish. This process enhances the stone's depth and vibrancy while improving stain resistance and ease of cleaning. For a more subtle look, honed finishes offer a smooth, matte appearance. Flamed finishes create a rough, textured surface, making them ideal for outdoor applications.

A Commitment to Quality: Beyond the Surface

Strict Quality Control: Moreover, Every slab and cut piece undergoes detailed inspections. Skilled technicians check for imperfections, monitor natural color consistency, and confirm exact dimensions. This step-by-step process ensures only flawless products leave the factory.

Technological Advancement: In addition, Advanced technology drives efficiency and precision. Modern factories use automated systems for handling, cutting, and polishing. These systems reduce errors, increase productivity, and help manufacturers deliver high-quality granite at competitive prices.

Skilled Workforce: Yet, Technology alone is not enough. Experienced craftsmen, engineers, and quality experts form the backbone of the process. Their knowledge and precision guarantee that every piece of Steel Grey granite meets international standards.

Global Reach: Bringing Indian Steel Grey to the World

Robust Logistics and Packaging: Additionally, Exporting heavy, fragile natural stone requires sophisticated logistics. Reputable manufacturers have established robust supply chains, collaborating with reliable shipping partners to ensure timely and secure delivery. Meticulous packaging, often using sturdy wooden crates and protective cushioning, safeguards the granite during transit, preventing damage and ensuring that the product arrives in pristine condition.

Customer-Centric Approach: Although, Understanding the diverse needs of international clients is crucial. Leading manufacturers provide excellent customer service, offering detailed product information, technical specifications, and timely communication. They often have dedicated export teams familiar with international trade regulations and customs procedures, simplifying the purchasing process for their global partners. This customer-centric approach fosters long-term relationships and builds trust.

Applications: Where Strength Meets Style

Kitchen Countertops: Steel Grey granite is tough and highly resistant to daily wear, making it ideal for busy kitchens.

Bathroom Vanities: Its natural elegance elevates bathroom interiors while providing a durable, low-maintenance surface.

Flooring: With its strength and durability, it performs exceptionally well in high-traffic residential and commercial spaces.

Wall Cladding: The consistent grey tones deliver a sleek, modern look for both interior and exterior walls.

Exterior Paving and Landscaping: Weather-resistant and long-lasting, it adds grandeur to patios, pathways, and facades.

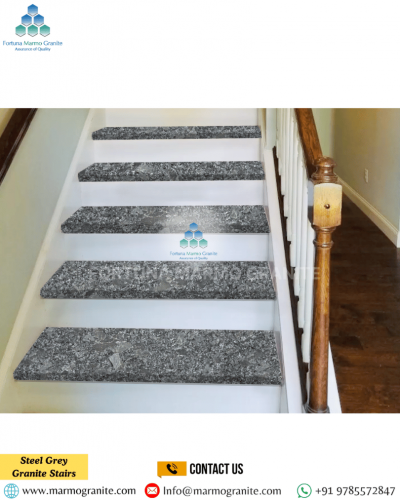

Architectural Elements: From sturdy staircases to decorative columns, Steel Grey granite offers timeless strength and sophistication.

Conclusion

Indian Granite Supplier Represents the perfect balance between modern sophistication and natural durability, making it one of the most sought-after granite varieties for a wide range of architectural and interior design applications. Yet, With its consistent dark grey background enriched by subtle specks of silver and black, it delivers a refined, elegant look that seamlessly complements both traditional and contemporary styles. Whether used for kitchen countertops, flooring, cladding, staircases, or exterior facades, this granite offers unmatched resilience against wear and tear, moisture, heat, and staining, ensuring long-lasting beauty with minimal maintenance. In addition, As a trusted Steel Grey Granite manufacturer from India, Fortuna Marmo Granite is committed to delivering excellence at every stage—from sourcing premium quality raw blocks to precision cutting, surface finishing, and international shipping.

Moreover, Our world-class infrastructure, experienced craftsmen, and strict quality control procedures enable us to meet the highest global standards. We work closely with architects, contractors, and distributors worldwide, offering customized sizes, finishes, and packing solutions tailored to diverse project needs. With a strong legacy in the natural stone industry and a focus on sustainable practices, Fortuna Marmo Granite is proud to be your reliable partner in bringing the bold beauty and enduring strength of Steel Grey Granite to life in projects across the globe. When you choose our granite, you're not just selecting a stone—you're investing in a product that is the result of deep geological heritage, expert craftsmanship, and a company dedicated to perfection.