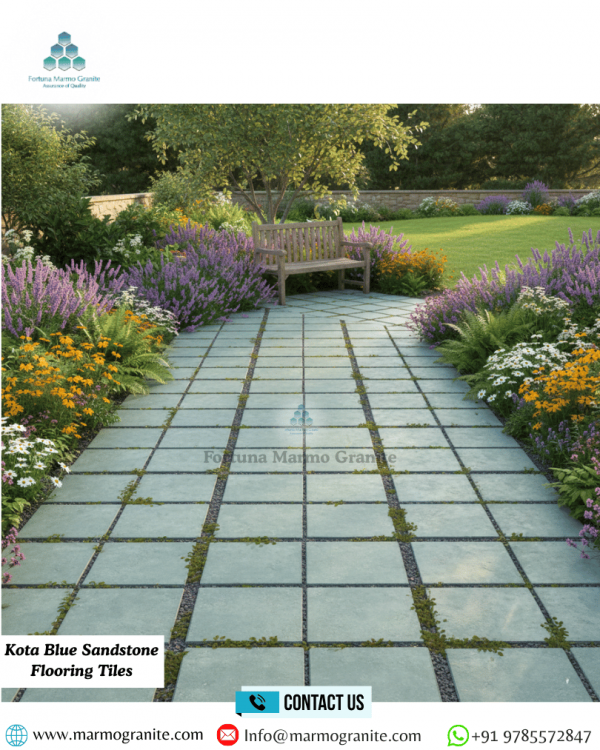

Kota Blue Sandstone Manufacturer from India: Premium Quality Stone for Global Projects

Kota Blue Sandstone Manufacturer, When you think of a building that stands the test of time, you probably imagine heavy, reliable, and beautiful natural stone. Among the treasures found in the heart of India, Kota Blue—often referred to as Kota Blue Sandstone or Limestone—is a world-class material that has captured the attention of architects and homeowners from London to Dubai.

Indian Sandstones Supplier, If you are looking for a stone that combines the ruggedness of a mountain with the elegance of a modern gallery, you've found it. In this blog, we'll dive deep into why this stone is a global favorite and why choosing the right manufacturer in India makes all the difference.

What Exactly is Kota Blue Stone?

First, let's clear up a common mix-up. While many people search for "Kota Blue Sandstone," it is technically a fine-grained limestone quarried in the Kota district of Rajasthan, India.

It is famous for its unique bluish-grey hue, often featuring subtle green or teal undertones. Unlike some stones that look artificial, Kota Blue has a natural, earthy texture that feels alive. It's a sedimentary rock, meaning it was formed over millions of years, resulting in a dense, tough, and incredibly durable material.

Why Global Architects Love Kota Blue

1. Unbeatable Durability

Kota Blue is one of the hardest natural stones available. It can withstand heavy foot traffic, making it the "go-to" choice for railway stations, hospitals, and shopping malls. It doesn't wear out easily; in fact, it often looks better as it ages.

2. Naturally Slip-Resistant

Safety is a priority in any construction project. Kota Blue has a naturally "non-slip" surface, especially in its honed or natural finish. This makes it perfect for:

- Swimming pool decks

- Public pathways

- Outdoor patios in rainy climates

3. Temperature Regulation

One of the most "human" benefits of this stone is that it stays cool. Even in the scorching heat of summer, Kota Blue doesn't absorb heat like concrete or granite does. Walking barefoot on a Kota floor feels refreshing.

4. Eco-Friendly and Sustainable

As a natural product, it requires very little processing compared to synthetic tiles. It is 100% recyclable and has a very low carbon footprint, making it a "green" choice for modern sustainable architecture.

From the Mines to the World: The Manufacturing Process

Step 1: Ethical Quarrying

The journey begins in the vast quarries of Rajasthan. Leading manufacturers use controlled drilling methods to extract large blocks without damaging the surrounding environment or the stone's integrity.

Step 2: Precision Cutting

Once the blocks are out, they are moved to the factory. Here, high-tech gang saw machines or block cutters slice them into slabs. Whether you need a standard 22mm thickness or a custom 30mm slab for a driveway, precision is key.

Step 3: Surface Finishing

This is where the magic happens. Depending on the project, the stone can be finished in several ways:

- Natural Cleft: Rough and rustic, great for outdoors.

- Honed: Smooth and matte, perfect for a modern indoor look.

- Polished: Shiny and reflective, often used for high-end flooring.

- Tumbled: Aged and soft edges, ideal for a "heritage" feel.

Step 4: Quality Inspection

A global manufacturer knows that one cracked tile can ruin a shipment. Every piece is checked for color consistency, thickness, and structural cracks before being packed.

Applications: Where Can You Use Kota Blue?

Choosing the Right Indian Manufacturer

When importing stone for a global project, you aren't just buying a product; you are buying a partnership. Here is what to look for in a Kota Blue manufacturer:

- Own Quarries: Manufacturers who own their mines can guarantee better price stability and quality control.

- Customization: Can they provide "cut-to-size" tiles for your specific architectural drawings?

- Packaging Excellence: For international shipping, the stone must be packed in strong, fumigated wooden crates with foam protection to prevent breakage during the long sea voyage.

- Experience: Look for companies that have a track record of exporting to Europe, North America, or the Middle East.

Maintenance: Keep It Looking New

Maintenance is surprisingly easy. For indoor floors, a simple mop with mild soap is enough. Unlike marble, Kota Blue doesn't stain easily. However, for outdoor use, it is often recommended to apply a penetrating sealer once every few years. This helps keep the deep blue color vibrant and prevents the stone from fading under harsh UV rays.

Pro Tip: Avoid using harsh acids to clean Kota stone. Since it is a limestone, acid can react with the calcium and cause "etching" or dull spots.

Conclusion

In conclusion, Kota Blue Sandstone stands out as a reliable and versatile natural stone choice for residential, commercial, and large-scale infrastructure projects worldwide. Its exceptional strength, uniform texture, slip resistance, and timeless blue-grey appearance make it ideal for flooring, paving, wall cladding, landscaping, and architectural applications. Sourced and processed with strict quality control, this durable sandstone ensures long-lasting performance even in demanding environments.

As a trusted Kota Blue Sandstone manufacturer from India, Fortuna Marmo Granite is committed to delivering premium-quality slabs, tiles, and custom-cut stone in various sizes and finishes, ensuring every global project receives consistent quality, competitive pricing, and dependable service.